A new-type recyclable filter material

Since the outbreak of the COVID-19 epidemic, masks have become important protective equipment, and also necessary supplies for front-line medical care, enterprises’ work resumption and people’s travel. However, with the continuous changes of the global epidemic situation, the market demand for masks is still huge. As a key material for filtering viruses and bacteria, mask filter material has also become an important factor restricting the improvement of mask production capacity. Shijiazhuang Chentai Filter Paper Co., Ltd. immediately organized technicians to independently develop a special filter material for masks—SecureGuard™ nano non-woven fabric, which can block and eliminate viruses and bacteria on masks. Compared with ordinary meltblown non-woven materials, Chentai SecureGuard™ new-type nano filter material can be reused while providing better protection. It is mainly used for daily protective and medical protective masks, and its protection level can reach N99 and P99. It can help address the global shortage of mask filter materials, and can also be used in automotive air conditioning filters, indoor air purifiers, industrial gas turbines and other filtration equipment.

A more environmentally friendly filter material that can be reused repetitively

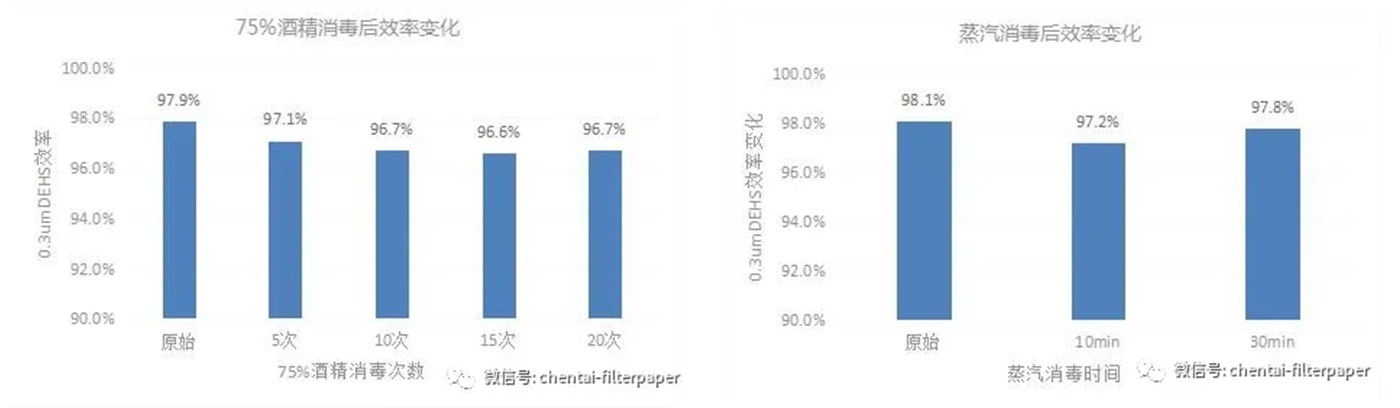

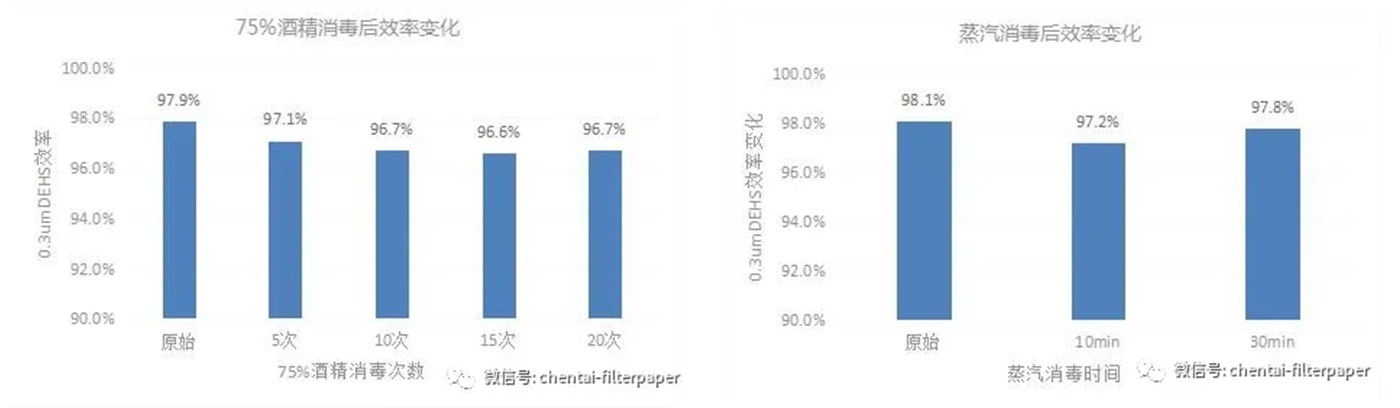

Chentai SecureGuard™ nano mask filter material can be disinfected and reused many times, and event more than 20 times upon alcohol or steam disinfection, thus saving wearing cost, and reducing resource waste and environmental pollution.

Effective sterilization and virus killing

We adopt a safe and efficient sterilization formula (4 log reduction in 1min, namely a reduction of 99.99% per minute) to quickly kill the bacteria and viruses stuck on the mask filter material. The advanced sterilization and virus killing technology can enable repetitive and safe use for a long time (more than 50 hours in total). It can not only provide safer protection, but also prolong the use time of masks.

Chentai SecureGuard™ nanomask filter material adopts industry-leading electrospinning nanotechnology, which can, relying on mature industrial nanoproduction, sophisticated equipment, and strictly controlled production process, achieve high efficiency and low resistance by controlling the diameter of fiber to below 200 nanometers, thus effectively blocking viruses and other pollutants without obstructing breathing. The SecureGuard™ nanomask filter is applicable to all oily and non-oily environments, and can be disinfected and reused many times.

High efficiency and low resistance

| Model | Grammage (g/m²) | Resistance (pa) | Particle filtration efficiency (9%) | Standard | Purpose |

| CTN007 | 33 | 53 | 83.0 |

TOPAS

11.1cm/s

0.3μm

DEHS | Flat masks for medical and daily protection |

| CTN007A | 33 | 60 | 84.0 |

| CTN008 | 33 | 61 | 86.4 |

| CTN008A | 33 | 70 | 87.5 |

| CTN010 | 40 | 97 | 96.7 | American standard NIOSH:N95, P95European standard EN149:FFP2 |

| CTN010A | 40 | 104 | 96.2 |

| CTN012 | 40 | 142 | 99.4 | American standard NIOSH:N99, P99European standard EN149:FFP3 |

| CTN012A | 40 | 160 | 99.5

|

With high efficiency and low resistance, Chentai SecureGuard™ nano mask filter materialcan meet the efficiency requirements of both oily and non-oily particles, without any reduction of efficiency during use. It can not only reach N95 and N99 levels of masks, but also reach P95 and P99 levels, thus providing safer protection.

Main purpose

At present, the new-type nanonon-woven fabric developed by Chentai has passed the testing of Guangzhou Inspection Testing and Certification Group Co., Ltd. (GTTC) and been officially put into production, which can help solve the scarcity of mask filter materials in the current market and contribute to the global anti-epidemic efforts.

The virus is ruthless while people are affectionate!

Unite as one!

Come on, China! Come on, world!